Confused about motor specs? Read the ultimate guide on how to choose the right industrial electric motor. Learn about torque, IP ratings, and efficiency from CTCMOTOR experts.

Selecting the correct industrial motor is not just about matching horsepower. It is about ensuring longevity, efficiency, and compatibility with your specific application. At CTCMOTOR, we see thousands of motor failures caused simply by incorrect specification during the purchasing phase. Whether you are replacing an old unit or designing a new system, this guide will walk you through the critical factors.

The first step is understanding what the motor will drive. Is it a variable torque load like a centrifugal pump or fan? Or is it a constant torque load like a conveyor belt or extruder?

- Variable Torque: Requires less torque at low speeds. Standard induction motors often suffice.

- Constant Torque: Requires full torque at all speeds. You may need a motor designed for VFD (Variable Frequency Drive) operation to prevent overheating at low RPMs.

Where will the motor live? If your facility is dusty or prone to water splashes, a standard open drip-proof (ODP) motor will fail quickly.

- TEFC (Totally Enclosed Fan Cooled): The industry standard for most industrial applications.

- IP55 vs. IP65: If you are in a washdown environment (like food processing), ensure you choose IP65 or higher.

- Hazardous Locations: For oil and gas applications, explosion-proof motors are non-negotiable.

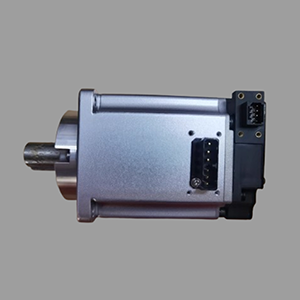

[INSERT IMAGE 1 HERE: A professional, clean graphic showing a cross-section of an industrial motor with key parts labeled like ‘Stator’, ‘Rotor’, ‘Bearings’, highlighting engineering precision.]

Energy efficiency is no longer optional. With rising global energy costs, the difference between an IE3 (Premium Efficiency) and an IE4 (Super Premium) motor can mean thousands of dollars in savings per year.

- IE3: The current mandatory standard for most regions.

- IE4: Higher upfront cost, but significantly lower operating temperature and extended bearing life.

- Recommendation: For motors running >4000 hours/year, always choose IE4.

Don’t let a poor motor selection stall your production. At CTCMOTOR, we provide personalized sizing services to ensure you get the perfect fit for your application. [Contact our engineering team today] for a free consultation.